The aim of the energy diagnosis test module is to determine

possible causes of a breakdown due to a flat battery or problems in the

vehicle electrical system

A breakdown due to a drained battery or problems in the vehicle

energy system can have a wide range of causes which, in most cases, are

not caused by the battery itself. For this reason, replacing the battery

will only rarely provide a sustained solution to the problem. The

energy diagnosis procedure helps find the cause of the problem.

Result of the energy diagnosis

The procedure reads all the necessary data from the corresponding

control units. After evaluating this data, it displays the following

information:

Conspicuous information: this information is only displayed if there

was a problem in the vehicle energy system. The number of information

items varies. This information includes the possible causes of a flat

battery or a vehicle electrical system fault. Look at the list of

possible fault causes, then select the number of the relevant causes in

order to bring up detailed information, instructions and the associated

diagnosis codes. If there are several possible fault causes, they are

listed in order of the kilometer reading at which they occurred (most

recent first). For example: the vehicle does not ‘go to sleep’ (sleep

inhibitor); the vehicle is wakened time and again; the side lights were

switched on for too long, etc.

Standard information: This information can always be displayed (driving

profile, stationary profile and – only if an IBS is fitted – evaluation

of the closed-circuit current measurement data, information on the

battery, for example battery charge state, of the last 5 days).

On the basis of this information, it can then be decided what the real cause of the fault is.

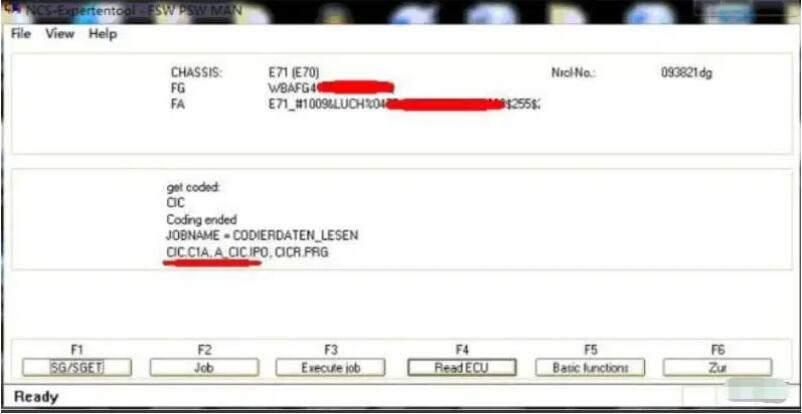

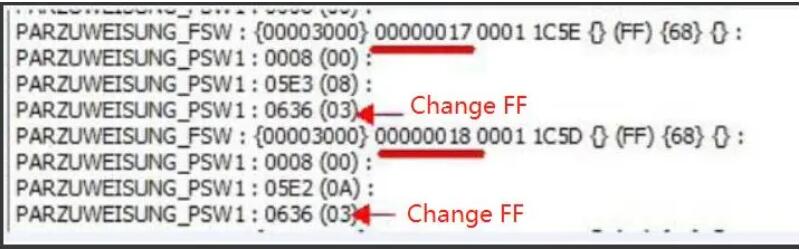

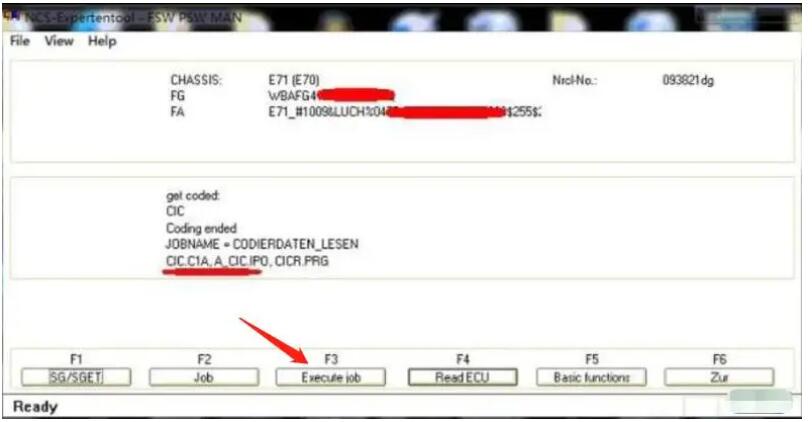

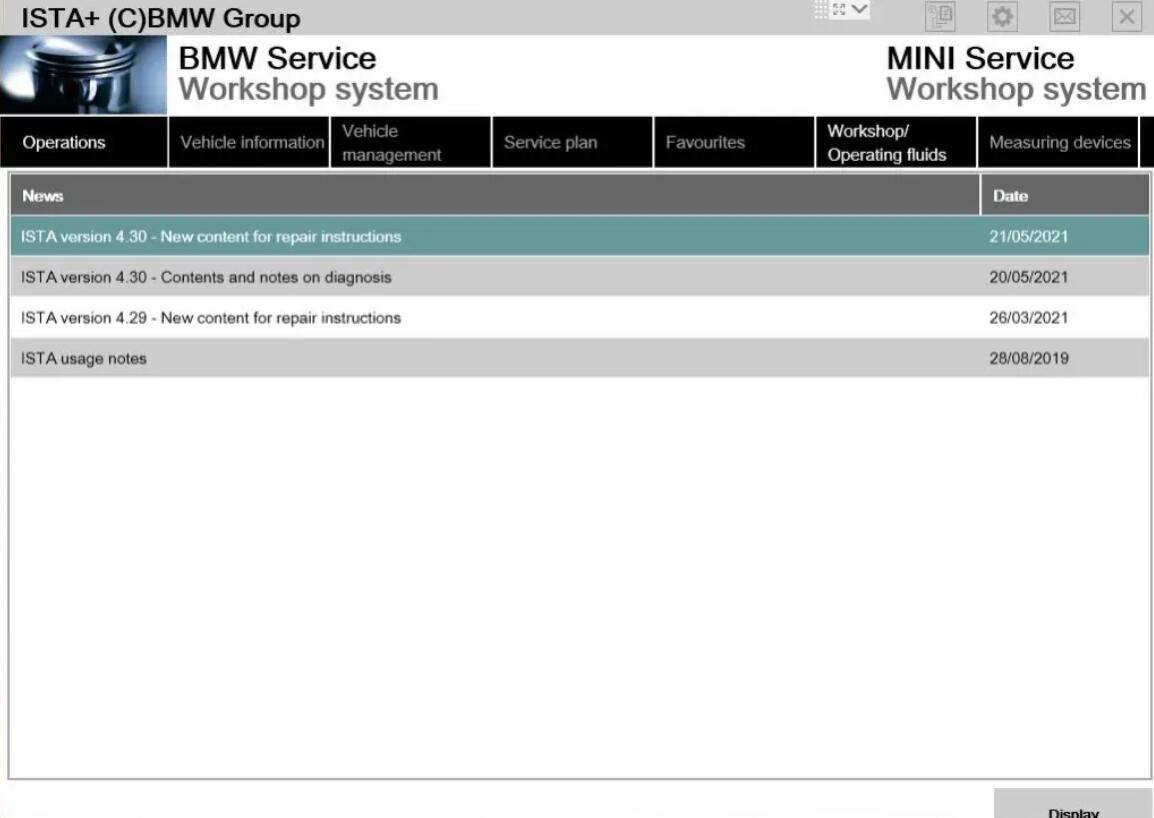

ISTA Energy diagnosis screenshotISTA Energy diagnosis

Overview of possible causes

A breakdown due to a drained battery or a problem in the vehicle

energy system is not necessarily the result of a faulty battery. The

various causes for discharge of the battery can be placed in two main

categories:

Vehicle faults:

Vehicle does not assume sleep mode.

The vehicle keeps being woken up.

Standby current too high in rest state.

Faulty alternator (poor charge balance)

Faulty battery.

Unfavorable customer behavior:

Side lights, parking light or hazard warning flashers were switched on for too long.

Terminal R or Terminal 15 switched on for too long

Long immobilization period.

Unfavorable driving profile (short-distance driving).

Frequent use of auxiliary consumers or use of auxiliary consumers for a

longer period (increased power consumption at a standstill).

Data from the vehicle that is read and evaluated

For energy diagnosis, the evaluated data in the vehicle is not

changed. The energy diagnosis can be run a number of times and normally

always provides the same result. The energy diagnosis normally provides

the same result after repairs, as the data is still present in the

vehicle. Even after deleting the fault memory, the data from the energy

history memory is still stored. However, at the latest when the energy

history memory is overwritten with new data, the repaired fault cause is

no longer displayed as result of the energy diagnosis. This information

in detail:

Energy history memory in the JBE (Junction Box Electronics) The energy

history memory (NB: do not confuse with the history memory for fault

entries) stores various bits of information that can assist in

establishing the cause of problems with the vehicle energy system. The

stored information of the energy history memory in detail:

The maximum number of waking’s within an off-load phase (terminal R off) within the last 5 weeks

The last 5 control units that prevented the vehicle from going to sleep (with kilometer reading of each event)

The driving profile of the last 5 weeks:

The driving profile is stored in the energy history memory with 6 data

records. Each data record contains the following information: Starting

time of record the data record, distance travelled in km during

recording, number of journeys in different ranges. A new data record is

started as soon as the time difference between the current time and

starting time of recording of the current data record is greater than 7

days. This means the time span of the evaluation is usually approx. 35

days if the vehicle was not immobilized for a longer period without

being wakened. When all 6 data records in the data memory are full, the

oldest data record is overwritten.

As of model year 03/2007 (JBE2), the last CAN messages that woke the K-CAN bus (with kilometre reading of each event)

Fault code memory in the JBE

If a bistable relay is fitted, the causes of cutoff of terminal 30g-f

are stored in the JBE. There are the following fault cases:

The battery reached the starting capability limit at terminal R off.

Up to model year 09/2006: 60 minutes after terminal R off, the vehicle has not yet switched into the rest state.

As of model year 03/2007: The vehicle is not yet in the idle state 10 minutes after cutoff of terminal 30g.

Up to model year 09/2006: The vehicle was wakened unexpectedly at terminal R off more than 30 times.

As of model year 03/2007: The vehicle was awakened unexpectedly more than 20 times after cutoff of terminal 30g.

Diagnosis requests of the DME/DDE

The DME/DDE stores various data that is used for the energy diagnosis:

If an IBS is fitted, the last 32 cycles of the closed-circuit current monitoring are stored

The last registered battery replacement

If an IBS is fitted, the state of charge of the battery of the last 5 days

The kilometre readings of the last 5 days

If an IBS is fitted, the auxiliary consumer units that were switched on

during the last 32 cycles, for example, light or independent heating.

Fault memory in the DME/DDE – If an IBS is fitted, the DME/DDE stores a

fault code memory entry in the event of a closed-circuit current fault

and total battery discharge.

Fault code memory of the FRM (footwell module) – The FRM is responsible

for control of the lights. At terminal R off, the FRM switches the

lights off if the voltage falls below approx. 11 V. On cutoff, a fault

entry is stored. At undervoltage, the FRM stores a fault code memory

entry. The environment related conditions can be used to determine

whether terminal R, terminal 15 or a statutory consumer unit (e.g. light

or hazard warning lights) was switched on.

NOTE:

For the following vehicles the energy diagnosis test procedure should

be worked through in the event of the complaint “flat battery”:

Unfavorable customer behavior with vehicle faults is a possible cause

of breakdowns due to a depleted battery. In detail, the following

individual causes can be determined:

Vehicle does not ”go to sleep”

If the vehicle does not reach the rest state after terminal R Off,

i.e. the bus systems remain active, the causing control unit is normally

determined by the energy diagnosis. The troubleshooting must be

continued in the peripherals (e.g. faulty sensor or switch) of each

control unit. If no fault is determined, renew the control unit. If a

number of control units on the PT‐CAN bus are entered as cause in the

energy history memory at the same kilometer reading, the wake-up line

should be checked:

Short circuit to ground or positive

Loose contact

First, check the connections of the wake-up line on the IBS (if fitted), CAS and JBE

In the case of 1-Series and 3-Series produced before 12/2006 with

fitted IBS: If terminal 15 can no longer be switched using the

start/stop button or the electric steering lock (ELV) cannot be

unlocked, check the installation location of the battery for traces of

dampness and examine the fault entries regarding the IBS: The IBS may be

faulty due to moisture and keep the wake-up line at high level. In this

case, replace the IBS. For vehicles produced after 12/2006, a new

water-tight IBS is used. Important! Operation by the customer can also

lead to an entry in some control units: e.g. listening to the radio with

terminal R OFF leads to the registration of RAD, RAD2 or M‐ASK and

possibly CID with the same kilometer reading as cause in the energy

history memory.

Vehicle keeps being woken up

If the vehicle is wakened time and again, the maximum number of

waking’s in an rest phase (terminal R OFF) for the last 5 weeks is

determined. The causing control unit cannot be determined automatically:

Identify the possible cause by disconnecting fuses or disconnecting the

corresponding control units step by step. If it was possible to

determine the waking control unit, troubleshooting must then be

continued in the peripherals (e.g. faulty sensor or switch, loose

contact) of the control unit. If no fault is determined, the control

unit must be renewed.

NOTE:

In exceptional cases, it is possible that the result ”Vehicle keeps

being woken up” is generated by unfavorable customer behavior, e.g.

frequently waking the vehicle at terminal R OFF by opening and closing

the tailgate or doors.

Excessive standby current

The result ”Excessive standby current” means that the vehicle,

occasionally at least, has had a standby current greater than 80 mA.

Here, the vehicle was in the rest state, that is, the bus systems were

inactive. A possible cause of this could be faulty control units. As

troubleshooting, run a standby current measurement and identify possible

causes by disconnecting fuses or disconnecting the corresponding

control units step by step.

Battery or alternator faulty

Even though the battery was not the cause of the complaint, it might

have been damaged beforehand due to total discharge for a longer period.

For this reason, check the battery condition if you suspect that the

battery might have been damaged beforehand. If there is a suspicion that

the alternator is faulty, it must be determined whether the DME/DDE has

relevant fault entries. Fault entries with regard to the IBS must also

be taken into account. If the vehicle comes to a standstill and will not

start during or shortly after a journey, the cause probably lies in the

charge balance of the alternator. A requirement here is that the

charged battery was still able to deliver adequate current for the

starting operation.

E65, E66, E67 from model year 03/2004,-E60, E61, E63, E64, E70, E71,

E72, E81, E82, E84, E87, E88, E89, E90, E91, E92, E93, -All F Series

from F01, -All MINIs from R55, -RR04

If you want to know more about BMW ICOM information, please visit Obd2tool.com