What is Coding?

It is a process utilized by BMW, which groups system specific

operating requirements (Data) together and then assigns a label/code to

each of these groups of data. The various groups of data are all

pre-loaded into system specific “codable” control modules, along with a

basic set of operating instructions (Program).

There are various types of operating requirements such as; O2

sensors, emissions controls, fuel type, Manual or Auto transmission.

The procedure of assigning one specifically labeled group of data to

the operating program of a specific control module/component is referred

to as “coding”. Coding allows a specific set of data already present in

the module to be selected.

A “codable” control module has a basic operating program already

installed along with several specific variations of operating data. The

coding process allows a specific set of operating data to be assigned to

the basic operating program of that module/component, with respect to

its specific application.

Coding can be performed for some systems/components via ISTA/P

or the older DIS/Plus/GT1/SSS device. By entering a variant code via

the device, selecting customer specific operational settings from a list

of available features (VKM) or automatically by selecting a specific

coding process.

Note: Codable control modules/components are system specific, which means that not all control modules are codable.

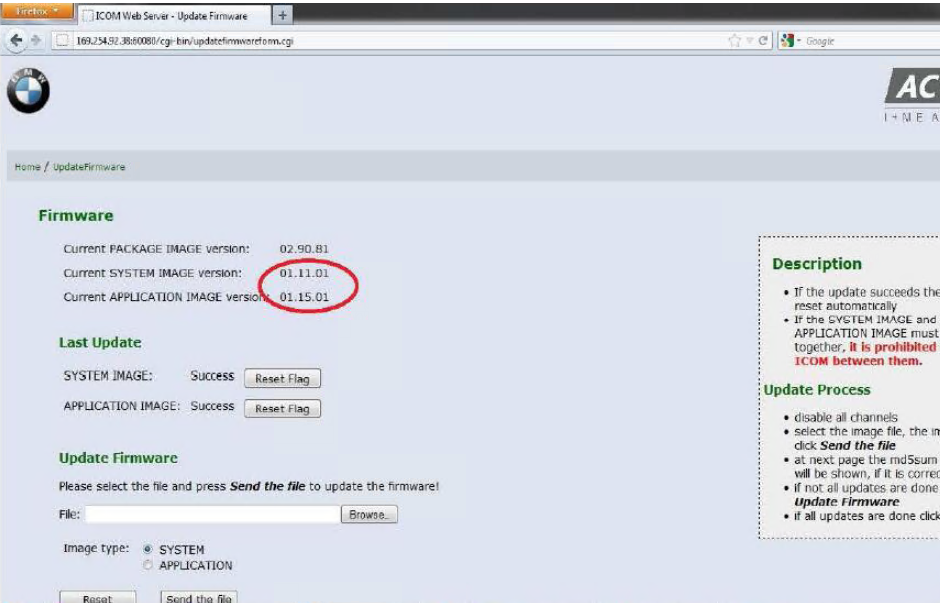

What is Programming?

It is a process utilized by BMW to load application/system specific

operating instructions. Programming loads control functions instructions

into a specific control module.

(Program) into a module/component which already has the systems

operating requirements (Data) installed, plus it can be used as a means

of updating data and operating instructions previously installed in a

control module. Basic programmable control modules have a pre-defined

set of operating data already installed which allows the module to be

fairly generic until a specific operational program is installed.

The ability to program a module is limited to the number of times it

has already been programmed and the hardware version of the control

module itself.

What is I-level (or Integration Level)?

The ECU’s in a BMW are not meant to be updated individually, rather

as a collection which BMW tested and knows all work fine together. The

collective version number of all programmed ECU’s is called the I-level,

or Integration level (German: I-stufe). The term I-level was adopted by

BMW around the year 2004 and applies only to lines which were in

development/production in 2004 or after (E60, E70, E90, etc.).

The I-level is a set of numbers that looks like E89X-11-09-410. The

first part represents the chassis group, which is followed by the year

and month of the release and a build number for that release. So,

E89X-11-09-410 would mean an E80/E90, 09/2011, version 410.

You will often see a set of two I-levels, something like

E89X-05-10-026, E89X-11-09-410. In this case the first set is called the

Factory I-level, or the level with which the car left the factory, and

the second the Dealer Organization I-level, or the current version

programmed by the dealer.

Tagged on: bmw encoding, bmw programming, E36, E39, E46, E60, E61, E63,

E64, E65, E66, E67, E70, E71, E72, E81, E82, E84, E87, E88, E89, E90,

E91, E92, E93, F01, F10